Engineering

Engineering

Rely on the expert

Engineers for tomorrow’s world

Schulz Engineering has been a leader in the design of innovative and highly flexible body-in-white and production systems for decades. As an engineering partner, we have been supporting OEMs and suppliers with a broad and comprehensive product portfolio for over 40 years. As a highly qualified team of technicians, software developers and engineers, we stand for excellent engineering technologies.

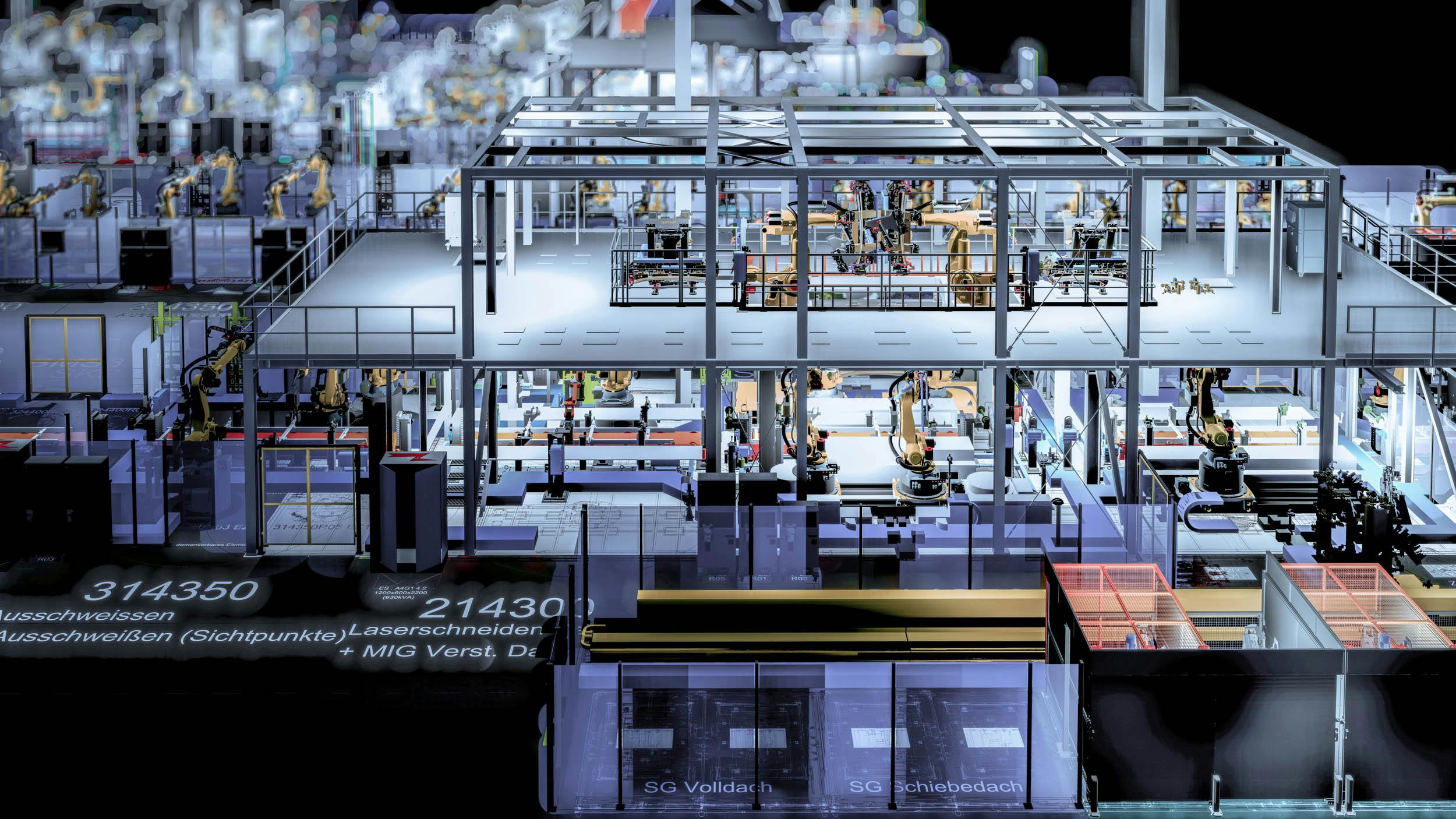

In the digital factory from concept planning to detailed planning

From the clamping concept and 3D design to the production drawing

Robot simulation, offline programming and availability simulation

Risk analysis according to machine guidelines and CE documentation

In over three decades, we have been able to successfully design and implement a wide variety of projects by means of our broad expertise.

These include:

- Building framing systems

- Battery assembly systems

- Small series

- Best-fit finish line

- Engine hood and tailgate robot plants

- Manual finish lines

- Side panel production lines

- Doors robot plants

- Body subgroups robot and manual lines

- Body robot production lines with skid technology

As we offer a wide range of services in addition to the usual process technologies, we can always take our customers' individual needs and requirements into account. Our strength lies in hybrid construction with steel and aluminum, as well as in composites with CFRP.

- Clinching

- Bonding

- Laser soldering

- Laser welding

- MIG/MAG

- Riveting

- Screwing

- Resistance welding

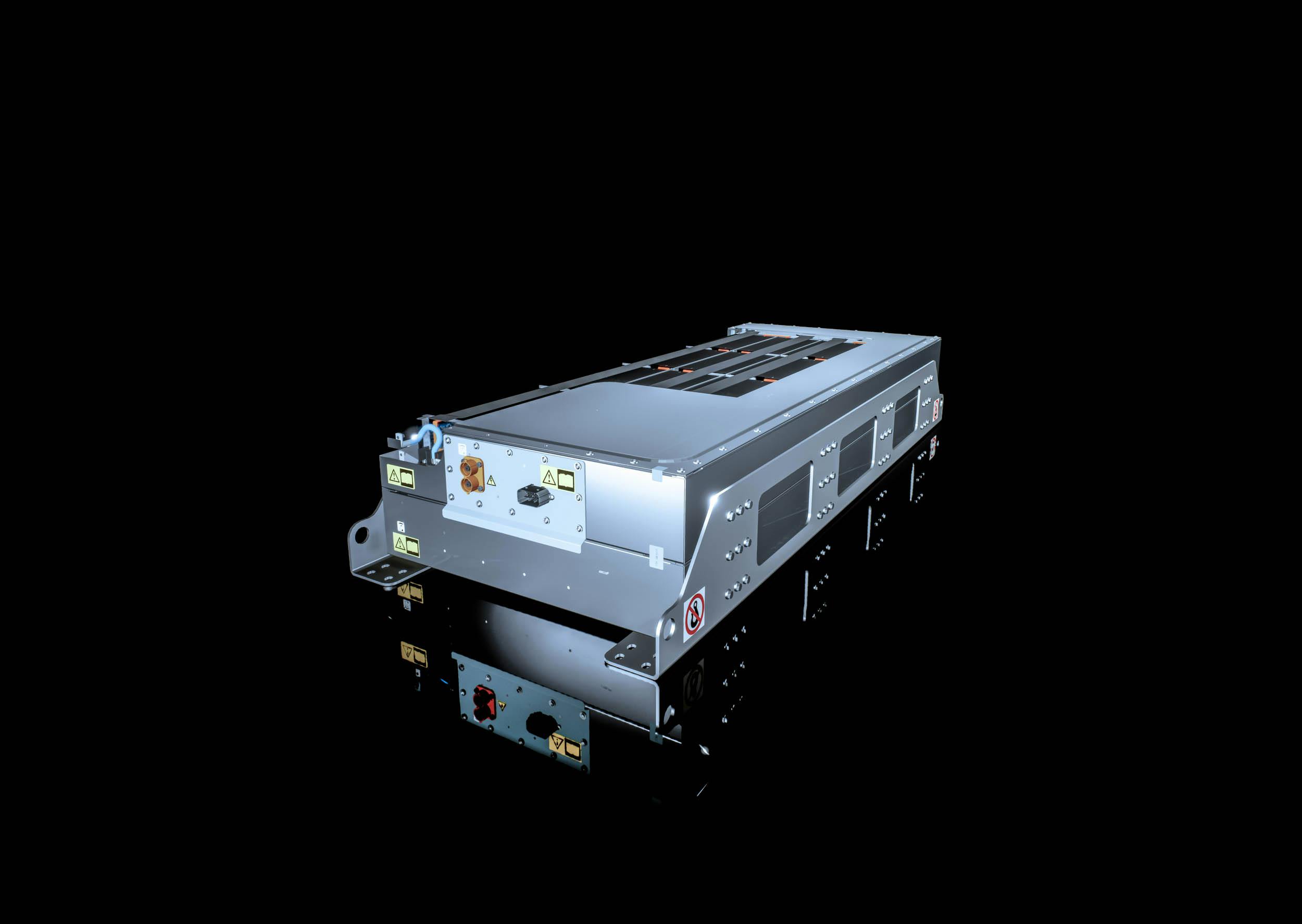

The future goes electric

Electromobility

In electromobility, we support our customers with our expertise in the assembly of battery systems and modules.

In battery production, we support you in the entire concept planning for the production of battery systems in flexible assembly and testing technology, including the planning of production requirements such as emergency concepts and cell material handling.

Our close cooperation with one of the leading manufacturers of high-performance lithium-ion battery systems means that our employees are always up to date with the latest production technology requirements.

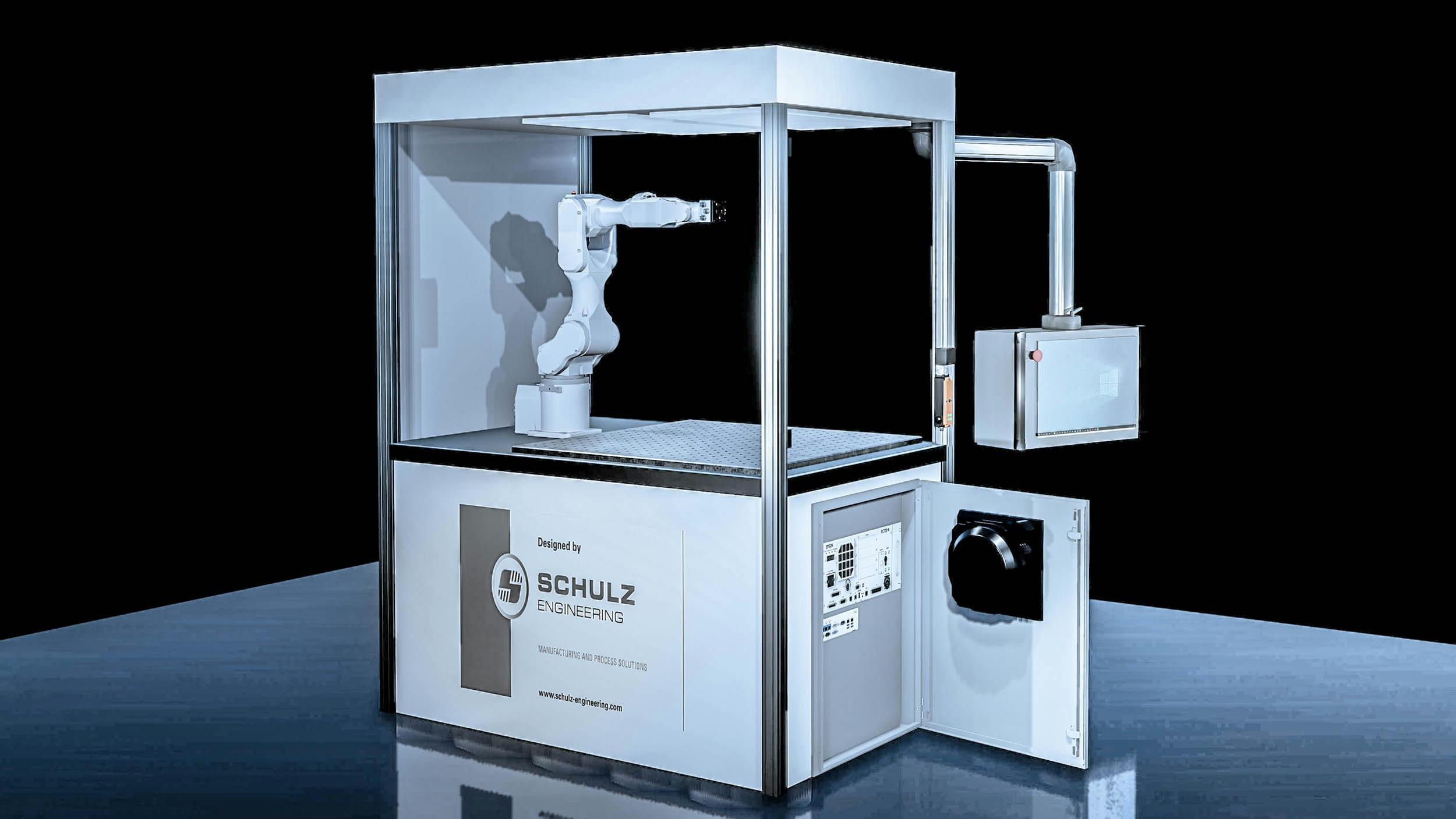

Customized end-of-line testers to safeguard your production processes.

Our portfolio includes the optical final inspection with camera technology up to the battery test bench.

We work together with our sister company h-kon GmbH to deliver a complete system from construction to commissioning on site. We have already planned, designed and implemented several battery assembly systems in close cooperation with AKASOL AG.

Systems in Engineering

- Catia V5

- NX

- Inventor

- Solidworks

- Robcad

- Process Simulate

- Delmia Robotics V5

- Kuka KRC und VKRC

- Fanuc

- Motoman

- ABB

- Process Designer

- Micro Station

- APIS

- PLATO

- SafeExpert

- FARO Laser Tracker

- Trimble 3D Scanner

- Trimble Realworks Performance Software

- ELAM - Armbruster Engineering GmbH

- EPLAN P8

- Simatic S7 und TIA Portal

- Beckhoff TwinCAT 3

- Festo Fluid Draw

- EPLAN Fluid

- Plant Simulation Siemens

We accompany you into the future

Industry 4.0

Production lines are planned within the digital factory at Schulz Engineering.

The digital twin of the production line contains the real geometric dimensions and the requirements of the production processes. The system concepts are mapped in virtual reality 3D simulation systems to validate the system and process concepts in advance for production areas and logistics during planning. The output of the production lines is verified with a dynamic simulation model according to VDI 3633.

For production lines with manual workstations, we can offer planning and implementation for a worker assistance system with traceability and quality gates.

In this system, smart devices such as screwdriver controllers, automatic testing machines, etc. are integrated with OPC UA and the process parameters are stored. PLC automatic stations can also be connected to the system.