Project Management

Project Management

Over 800 successful projects

We realize your projects

Our team of experts offers you an all-round package, starting with concept development, tendering and selection of suppliers right up to overall budget overview and on-site control of the project's timely implementation.

In order to optimize development and innovation times and thus ultimately shorten them, projects are implemented using simultaneous or concurrent engineering. In this process, product technologies and production design are developed in parallel. With superior experience in plant engineering and creative lateral thinking, we can come up with completely new ideas, surprising approaches and solutions for you!

360-degree project management

Schulz Engineering customer projects follow a predefined standard, the Schulz Engineering Product Engineering Process, also called SE-PEP. The SE-PEP, which is anchored in our quality management, creates the prerequisite for the transparent and risk-minimized execution of the most diverse project requirements for a variety of customers. As an experienced problem solver for the most demanding tasks, our professional and certified project management not only controls project execution internally, but above all supports you in the implementation of your projects.

We are here for you

Contact us, we will be happy to advise you!

Further services

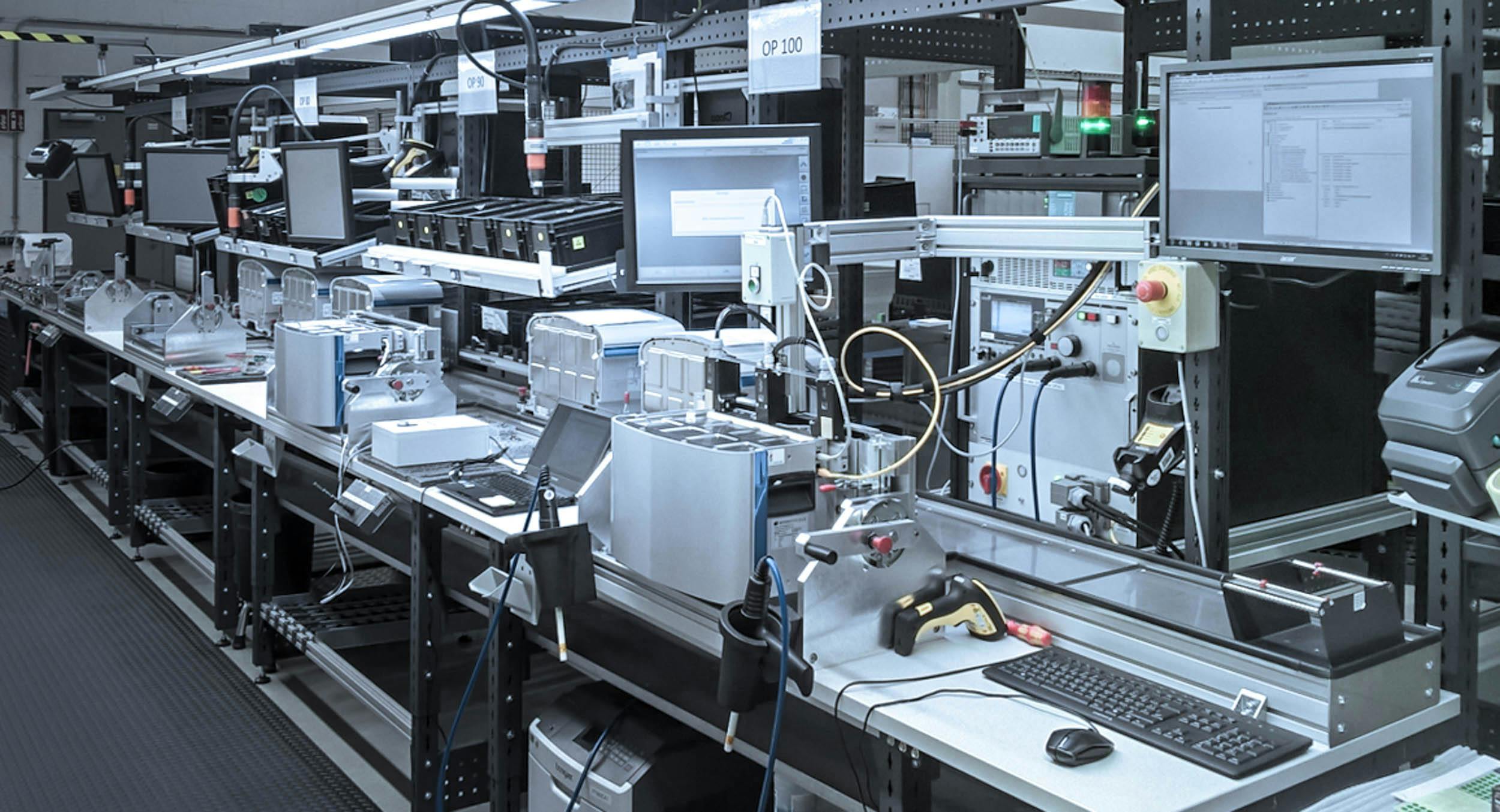

We are specialists in the design of special machinery and equipment in plant engineering. Our day-to-day operations not only include complete support for new constructions but also adapting and optimizing existing plants.

For worker guidance at the workplace and subsequent traceability of the manufactured components, we use the ELAM worker assistance system from our cooperation partner Armbruster Engineering.

Building on our experience and expertise gathered over many years, as well as our creativity, we can develop innovative plant concepts and system-optimized processes perfectly tailored to your needs.