Material Flow Simulation

Material Flow Simulation

Ahead of the future

Material flow and availability simulation

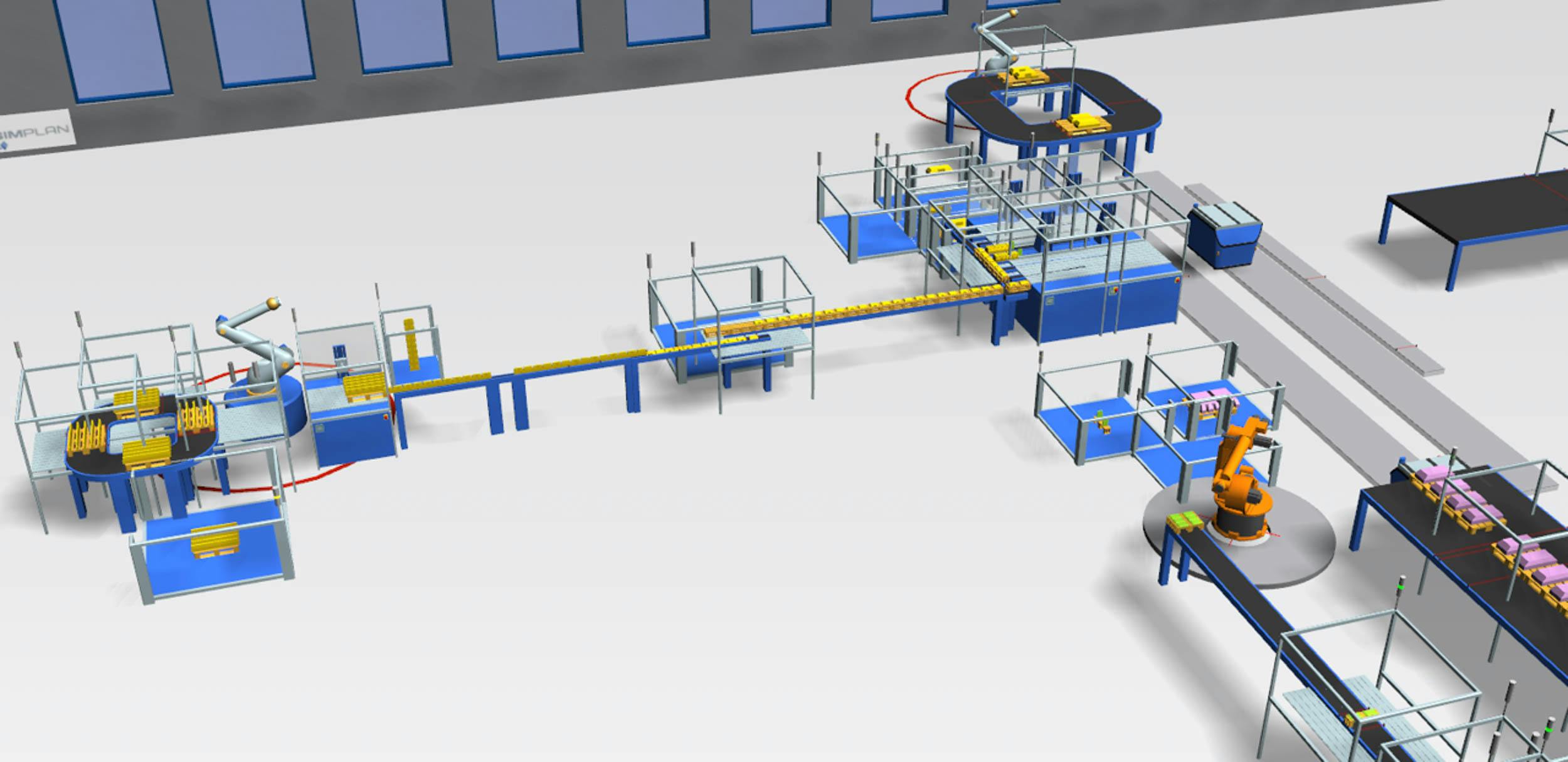

Material flow simulation allows you to react to events at an early stage, before the facts from reality are available. It can be applied in the deployment, feasibility, conceptual design and detailed design phases.

Before the SOP, our experts can digitally map all processes of complex production plants in our systems and test them for possible weak points as often as required. Existing plants can be systematically examined by means of material flow simulation in order to select and eliminate interfering factors.

In order to simplify decision-making processes without compromising quality, we offer you an individually developed decision support system. This allows you to optimize labor requirements, material handling and machine utilization, as well as identify supply bottlenecks at an early stage.

Availability simulation

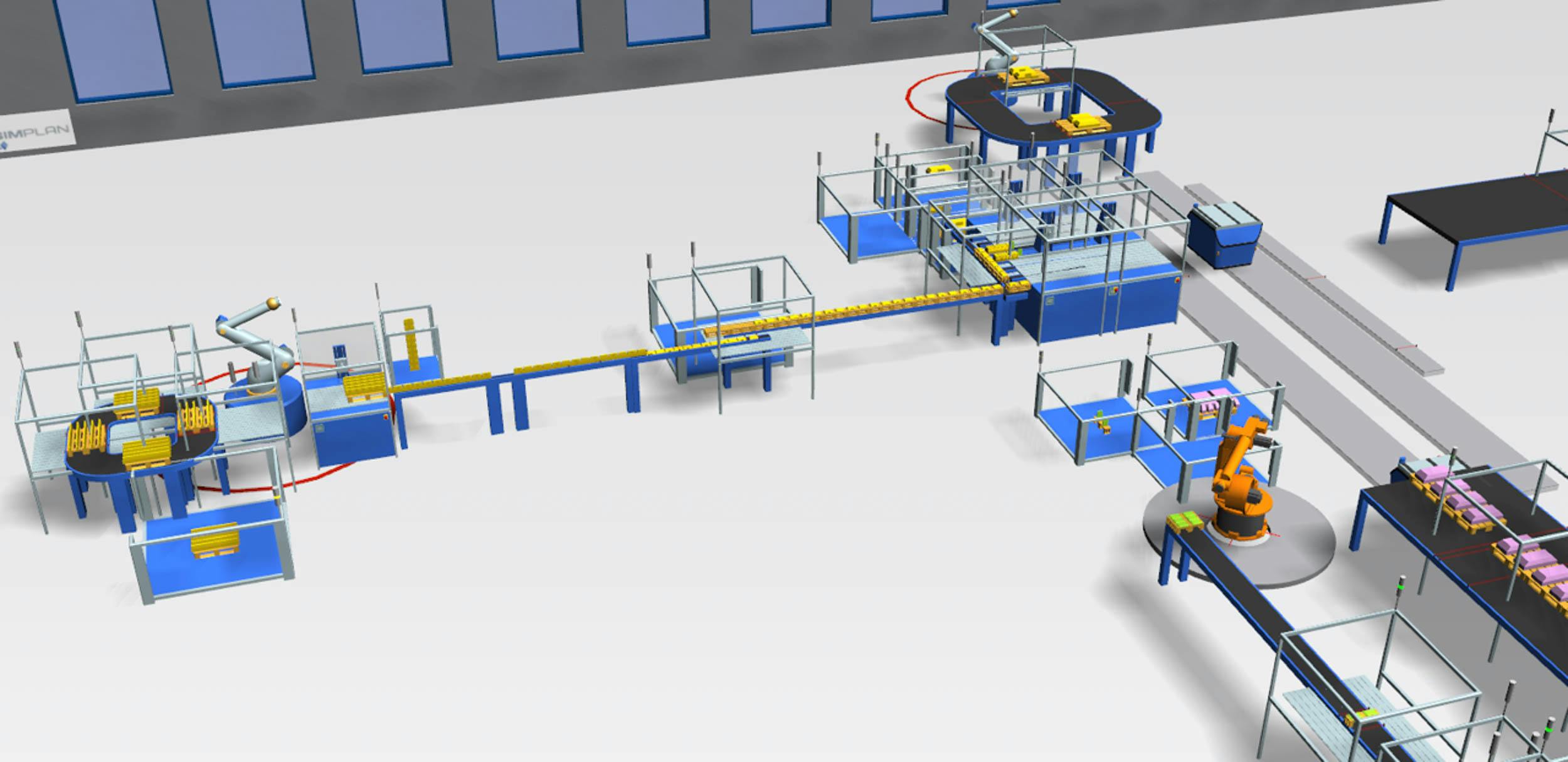

The output of an automated system depends to a large extent on the availability of the equipment used, i.e. the probability of failure of all components used. You also have to consider the duration and frequency of repair and maintenance work. For example, if you want to calculate a real number of output pieces, it is not enough to simply set the daily working time in relation to the cycle time. Any disturbance variables such as breaks, repair and maintenance work, logistics influences (missing components and set-up times) affect the output of a plant.

To calculate this, it is helpful to use availability simulations such as eM-Plant. Here, all disturbance variables are simulated over many days, with disturbances randomly generated in the correct ratio. The results can then be evaluated in a variety of ways:

- How high will the output really be?

- Do cycle time adjustments need to be made?

- How big do buffers need to be?

- What equipment is grouped together in a protective circuit?

- Is the equipment used sufficient (in combination with the cycle sequence)?

- How should you design the logistics process to eliminate waiting times?

We are here for you

Contact us, we will be happy to advise you!

Further services

Building on our experience and expertise gathered over many years, as well as our creativity, we can develop innovative plant concepts and system-optimized processes perfectly tailored to your needs.

Our team of experts offers you an all-round package, starting with concept development, tendering and selection of suppliers right up to overall budget overview and on-site control of the project's timely implementation.

We are specialists in the design of special machinery and equipment in plant engineering. Our day-to-day operations not only include complete support for new constructions but also adapting and optimizing existing plants.