Risk Analysis

Risk Analysis

With us you take no risk

Risk assessment from the expert

If you want to place machines or systems on the european market as a manufacturer, you are legally required to analyze every hazard associated with your machine by carrying out a risk assessment, so that you can draw up a list of measures to reduce these risks and identify them in documentation to protect employees.

We help you to keep track of the flood of directives, standards and laws and create a legally compliant risk assessment with you. We prepare the risk assessment using the SafeExpert database-supported standards system.

We can also offer you the following services:

- Testing for CE conformity

- Hazard analysis for workplaces

- Design of plant safety

- Design of safety zones

- Risk analysis and design of robot safety systems

- Overrun calculation for plants and machines

- Situational selection and design of safety technology

Creation of:

- Production line and machine documentation

- Operating instructions

- Instruction manual

- Safety instruction

- Work instruction

- Documentation of necessary evidence

- Security layout

We are here for you

Contact us, we will be happy to advise you!

Further services

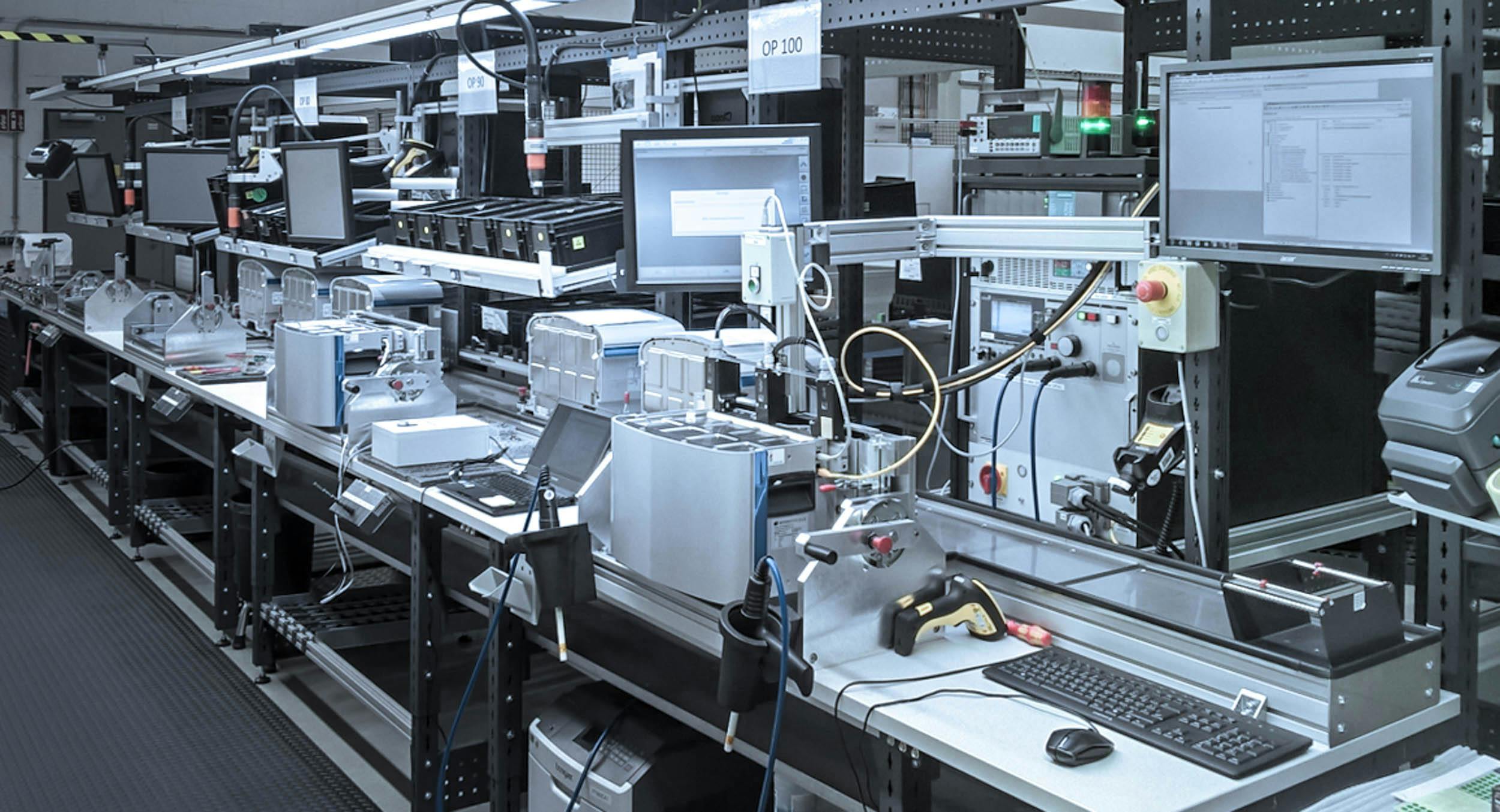

There are a large number of national and international standards for the implementation of the Machinery Directive 2006/42/EC. We help you to find your way through the jungle of laws, directives and standards and structure your documents to a necessary and sensible level.

For worker guidance at the workplace and subsequent traceability of the manufactured components, we use the ELAM worker assistance system from our cooperation partner Armbruster Engineering.

In this process, employees' manual work processes are analyzed to determine planned and target times. The entire process is reduced to basic movements (grasping, turning, etc.), the times are determined empirically and then tabulated.