Robot Simulation

Robot Simulation

All-round protection for your projects

Greater operational safety in the plant

With our robot simulations, we create a virtual environment to ensure in advance that the processes, plant design and worker safety are all guaranteed. Thanks to our broad portfolio of services, we are able to back up the simulation with a hazard and risk analysis using a wide variety of systems, e.g. SafeExpert.

Our all-round support

- Rough reachability simulation without clamping and recording technology

- 3D layout with placeholder for resources

- Rough area requirement planning and rough equipment quantity structure

- Robot type selection based on process capability and reachability

- Accessibility examination with 3D clamping and recording plan

- 3D layout

- Specifications for the design of the fixtures and handling systems in coordination with the process accessibility and reachability of the robot

- Simulation accompanying the design, introduction of the real design assemblies into the simulation

- 3D layout for foundation plan

- Check worker safety according to risk analysis and design of safety rooms

- Process path creation with RCS robot controller simulations for process time assurance

- Offline programming including the logic signals for controlling the systems and process devices on the robot

- Robot calibration with Faro Laser Trackers for measuring from the robots to the operating equipment

- Correcting the offline programs to agree with the corresponding robot calibration values

- Download the offline programs

- Importing and running OLP programs without PLC and process connection

- Automating robots with PLC and process devices

- Data feedback according to SOP

- Update of the digital twin to the real plant according to SOP

We are here for you

Contact us, we will be happy to advise you!

Further services

As experts in the field of robotics, we offer offline programming, online commissioning and start-up support. We work with various well-known manufacturers to program the right robots for your requirements.

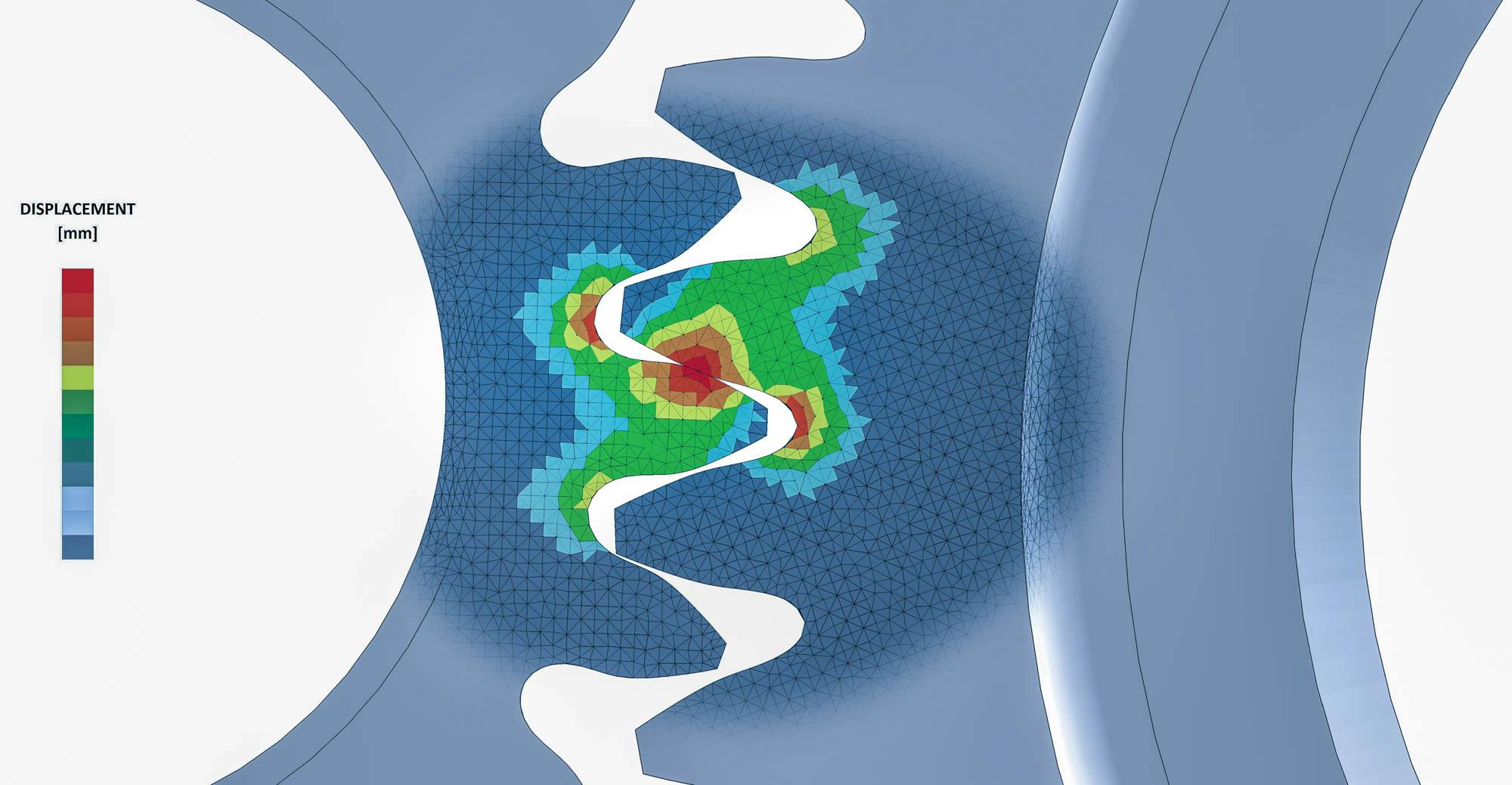

So that we can detect deformations, strains or stresses at an early stage in designs, we carry out calculations using the finite element method (FEM) based on complex solids. In this process, the total body is divided into several partial bodies in simplified forms, the “finite elements”.

With laser scanners, we can capture even complex and difficult-to-access systems for you, if necessary even during ongoing operation. By integrating additional geometries (CAD models), it is easy to perform collision checks, create placement variants or define conversion measures.