Worker Assistance System

Worker Assistance System

Engineering for smart factory together

Schulz Engineering and Armbruster Engineering

For worker guidance at the workplace and subsequent traceability of the manufactured components, we use the ELAM worker assistance system from our cooperation partner Armbruster Engineering.

The use of ELAM software creates agile and flexible assembly plants in which employees are supported by digital work instructions in assembly.

Factory 4.0

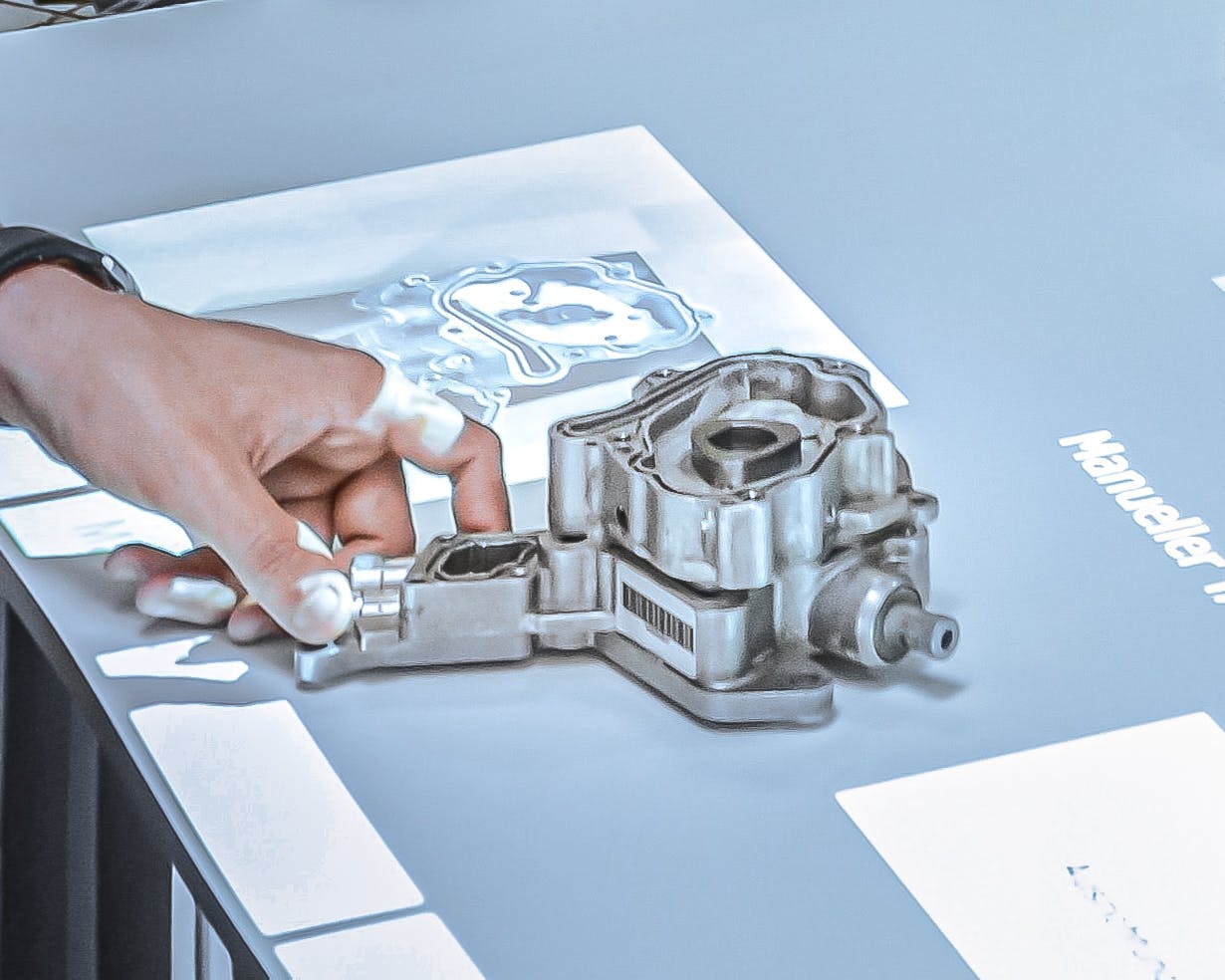

Each assembly process is visualized on a touch screen with the help of digital assembly instructions, known as worker guidance.

In this way, the employee is guided step-by-step through the assembly process, preventing errors and ensuring a controlled production flow.

Each assembly process is automatically evaluated and documented so that complete traceability can be guaranteed.

The digital assembly instructions are created and maintained centrally on a server for all assembly stations.

Smart tools can be easily connected to the ELAM system. Any hardware components can be included in the assembly process via corresponding controllers.

Tools, such as intelligent screwdrivers, robots, pick-to-light systems, presses or measuring equipment, can interact with the ELAM system depending on requirements.

All relevant process data is automatically stored in the database and can be viewed at a later date.

Product life cycle

Product life cycle record

At the start of an assembly process, a digital "product life cycle record" is created for each product.

Quality Gates

The entire evaluation of the assembly process is stored in the product life cycle record. It includes, for example, the status of the individual work steps (OK/ NOK), data of connected tools (e.g. screwing data), time and the name of the employee.

Traceability

For complete traceability, not only the product itself but also the components and materials used in the product are documented. Serialized material labels are scanned and stored to the assembly step in the product life cycle record.

The data on all possible processes, process points and also quality indicators are stored in the ELAM database and can be found quickly and easily.

The customer can view all the collected data via the ELAM web server either in the form of a product life cycle record or via a self-configured dashboard view.

Our partner Armbruster Engineering

Armbruster Engineering is our system supplier for ELAM software

Armbruster Engineering is an owner-managed company characterized by innovative products, consistent customer loyalty and continuous developments. For our customers, we realize a range of national and international worker assistance systems to improve production up to complex, industrial manufacturing plants. From receiving the order to shipping with digital worker guidance – interactive, error-free and traceable. At the same time, we draw on many years of experience from many successful projects in various industries. Agile, innovative action enables us to stay one step ahead of the broad market.

We are here for you

Contact us, we will be happy to advise you!

Further services

Our team of experts offers you an all-round package, starting with concept development, tendering and selection of suppliers right up to overall budget overview and on-site control of the project's timely implementation.

If you want to place machines or systems on the European market as a manufacturer, you are legally required to analyze every hazard associated with your machine by carrying out a risk assessment, so that you can draw up a list of measures to reduce these risks and identify them in documentation to protect employees.

Building on our experience and expertise gathered over many years, as well as our creativity, we can develop innovative plant concepts and system-optimized processes perfectly tailored to your needs